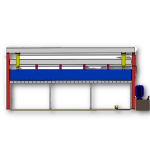

✅ Advanced Drive Systems: Options include Servo, Hybrid Servo, and Full Electric for optimal efficiency

✅ Precision Engineering: Finite Element Analysis (FEA) optimized frame ensures minimal deflection under load

✅ Rapid Operation: Fast downward speeds up to 240 mm/s and return speeds of 220 mm/s enhance productivity

✅ Automatic Tool Positioning: 6+4 axis systems enable quick die changes and minimize setup time

✅ Integrated Safety: Features OEM-embedded Lasersafe systems and safety light curtains for operator protection

✅ Energy Efficient: Hybrid servo technology reduces power consumption by up to 50% compared to traditional systems

✅ Industry 4.0 Ready: Capable of offline programming and digital twin integration for smart manufacturing

✅ CE Certified, ISO 9001, Noise Level <75dB

✅ Wide Capacity Range: Models available from 40T/1500mm to 300T/4000mm for diverse applications

Affordable Pricing:Cutting out middlemen, it directly benefits customers, reducing procurement costs by 10%-20% compared to middleman-sourced purchases.

Affordable Pricing:Cutting out middlemen, it directly benefits customers, reducing procurement costs by 10%-20% compared to middleman-sourced purchases. Overpriced:Marked up by middlemen, increasing procurement costs.

Overpriced:Marked up by middlemen, increasing procurement costs.